Why Do We Mine?

Mining stands as the bedrock of civilization, providing the raw materials essential for the functioning of numerous industries. From towering skyscrapers to the very roads we travel, the foundation of our modern world owes its existence to the extraction of materials from the Earth. Central to this process is quarrying, a crucial aspect of mining that delivers essential resources like crushed stone, sand, and gravel. But what is a quarry, and what materials does it produce? Let’s explain.

Definitions

In mining, the term “mine” typically refers to sites that produce metal ore or industrial minerals, such as gold, lithium, and bentonite, while “quarry” specifically deals with the extraction of crushed stone. Additionally, sand and gravel operations often involve the extraction of crushed stone without the need for blasting. Safety is the number one concern in the mining industry, particularly in the United States, where stringent protocols ensure the well-being of workers and the environment. Despite its checkered past, the mining sector is steadfastly marching towards a cleaner and safer future, continuously improving its standards in safety and environmental stewardship.

Location and Development

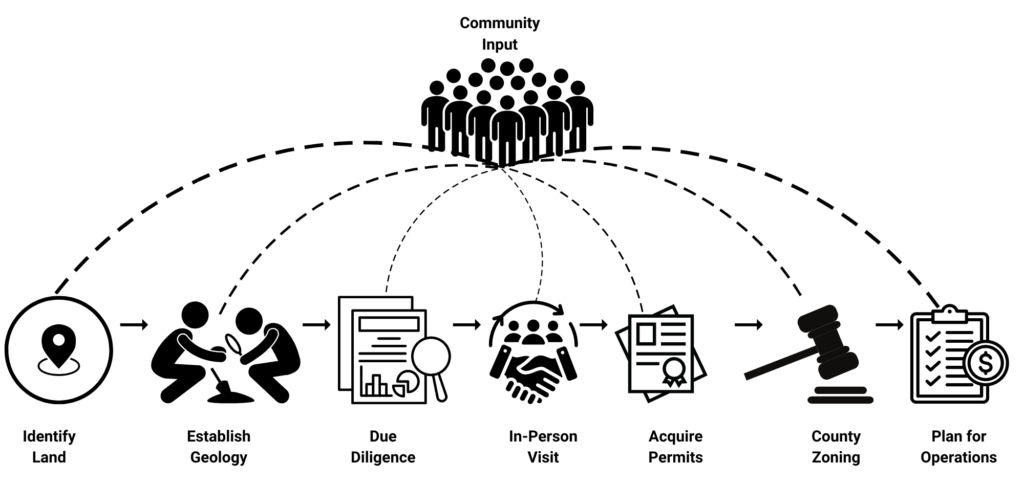

The success of a quarry hinges not only on its operational skill but also on the community’s acceptance and support. Engaging with local stakeholders and obtaining their input throughout the quarrying process is vital, provided the geological grades meet expectations. Prior to commencing operations, thorough due diligence is key. This involves assessing various factors such as market demand, the quality and quantity of reserves, property ownership, zoning regulations, and environmental considerations such as wetlands preservation. Leveraging cutting-edge technology like aerial imagery and Geographic Information Systems (GIS) aids in this assessment, enabling a comprehensive understanding of the quarry site’s market potential and challenges. Moreover, evaluating the transportation infrastructure, including rail and road networks, is crucial to ensure efficient logistics and minimize environmental impact.

Quarrying: Reclamation

Quarrying is not merely about extraction; it entails envisioning the endgame from the very beginning. Embarking on a quarrying venture necessitates envisioning what the landscape will become once the quarry reaches the end of its productive lifespan. How will the quarry further benefit the local community once it is past its lifespan? There have been many successful quarry reclamations that have further benefited the local community for years to come.

Economic Considerations

A mineral reserve is “the economically mineable part of a measured and/or indicated mineral resource. It includes diluting materials and allowances for losses, which may occur when the material is mined or extracted and is defined by studies at Pre-Feasibility or Feasibility level as appropriate that include application of Modifying Factors. Such studies demonstrate that, at the time of reporting, extraction could reasonably be justified.” What is a Mineral Resource? a concentration or occurrence of solid material of economic interest in or on the earth’s crust in such form, grade, or quality and quantity that there are reasonable prospects for eventual economic extraction”. Variations exist among different minerals. Precious commodities like gold and copper can maintain economic viability even at lower grades, thanks to their global demand and higher value per ton. Conversely, aggregate materials require larger quantities to be economically feasible, factoring in transportation costs. Thus, they are typically viable only when mined closer to their point of use.

https://thenugget.prospectorportal.com/what-is-the-difference-between-resources-and-reserves

Drilling in Quarries

The drilling phase of quarrying involves a variety of techniques tailored to suit the geological characteristics of the site. Hammer drills, commonly used for blasting, deliver percussive force to penetrate rock formations. Down-the-hole drills offer a quieter alternative, minimizing noise pollution while efficiently excavating minerals. Rotary weight push drills, another prevalent method, provide versatility and precision in challenging terrains, facilitating optimal extraction processes.

Conclusion

Quarrying stands as a cornerstone of modern civilization, providing essential materials that underpin various industries and infrastructural developments. By prioritizing safety, engaging communities, conducting diligent assessments, and embracing technological advancements, quarrying operations can navigate the complexities of extraction while mitigating environmental impact and ensuring sustainable resource management. As we unearth the treasures hidden beneath the Earth’s surface, let us do so with reverence, responsibility, and foresight, ensuring a legacy of progress and prosperity for generations to come.