In an era defined by rapid urbanization and increasing demand for infrastructure, the construction aggregate industry plays a pivotal role. However, as the need for raw materials grows, so does the importance of environmentally conscious quarrying. Implementing green practices in greenfield site selection not only benefits the environment but can also pave the way for operational efficiencies and an enhanced brand image. Let’s dive into the myriad of ways eco-friendly quarrying can be approached, from the early stages of site selection to advanced operational tactics.

1. Strategic Proximity to Transportation Hubs

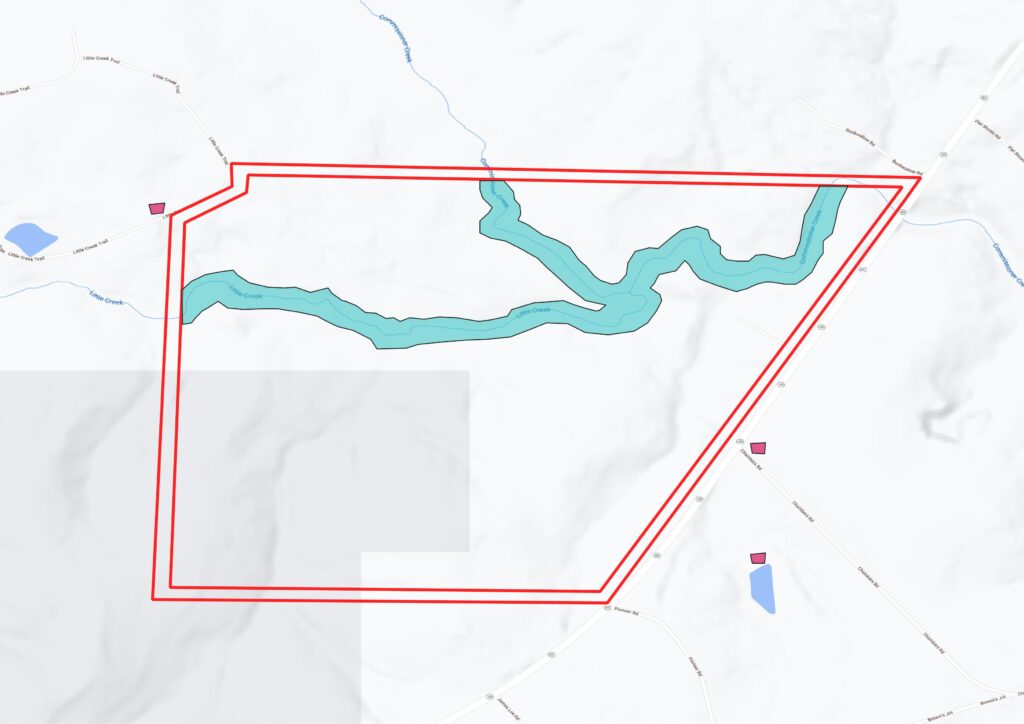

Selecting sites strategically close to major transportation hubs is a pivotal step in eco-friendly quarrying.

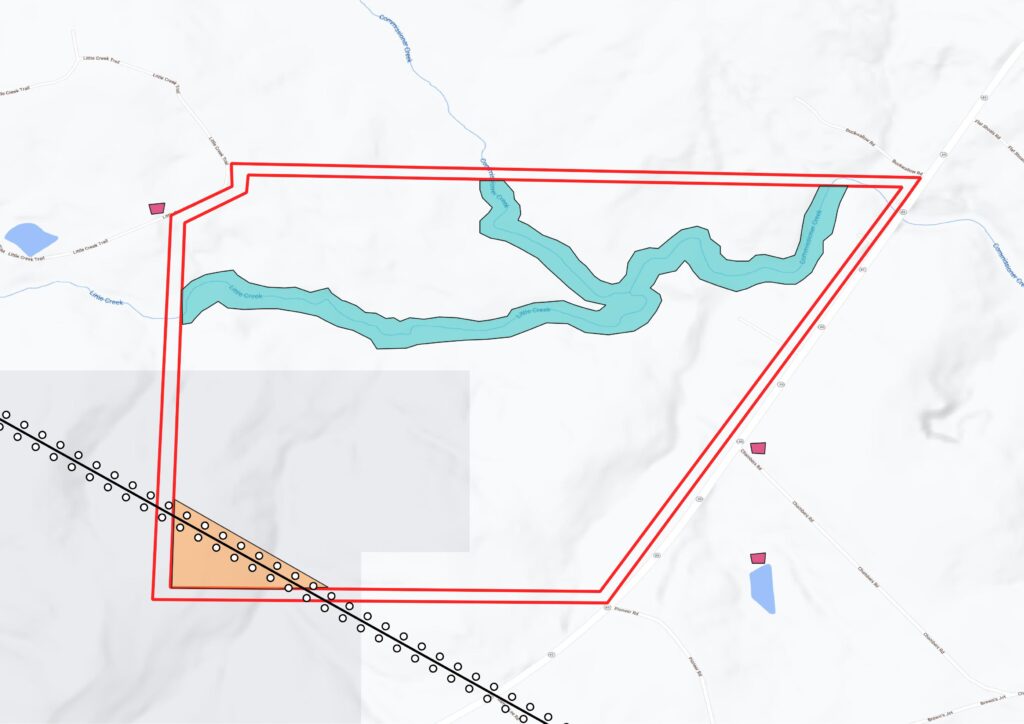

Rail Transportation: Rail remains one of the most energy-efficient means of bulk transport. By opting for sites near rail lines, quarries can directly load aggregates onto trains, which drastically reduces the carbon footprint per ton of material transported. According to the Association of American Railroads, railroads are, on average, four times more fuel efficient than trucks. This translates to fewer greenhouse gas emissions for the same freight load, making it a greener choice.

Reduced Road Traffic: Beyond the environmental implications, proximity to transportation routes minimizes truck travel distances, leading to reduced road congestion, fewer accidents, and diminished road wear and tear. This has an indirect environmental benefit by reducing the need for frequent road repairs, which itself is a carbon-intensive activity.

Dynamic Routing: Advanced technologies now allow quarry managers to utilize dynamic routing. By having a site close to multiple transport options, managers can dynamically select the most efficient transportation method based on real-time data, like traffic conditions, further reducing the environmental impact.

2. Thoughtful Mine Planning to Minimize Cycle Times

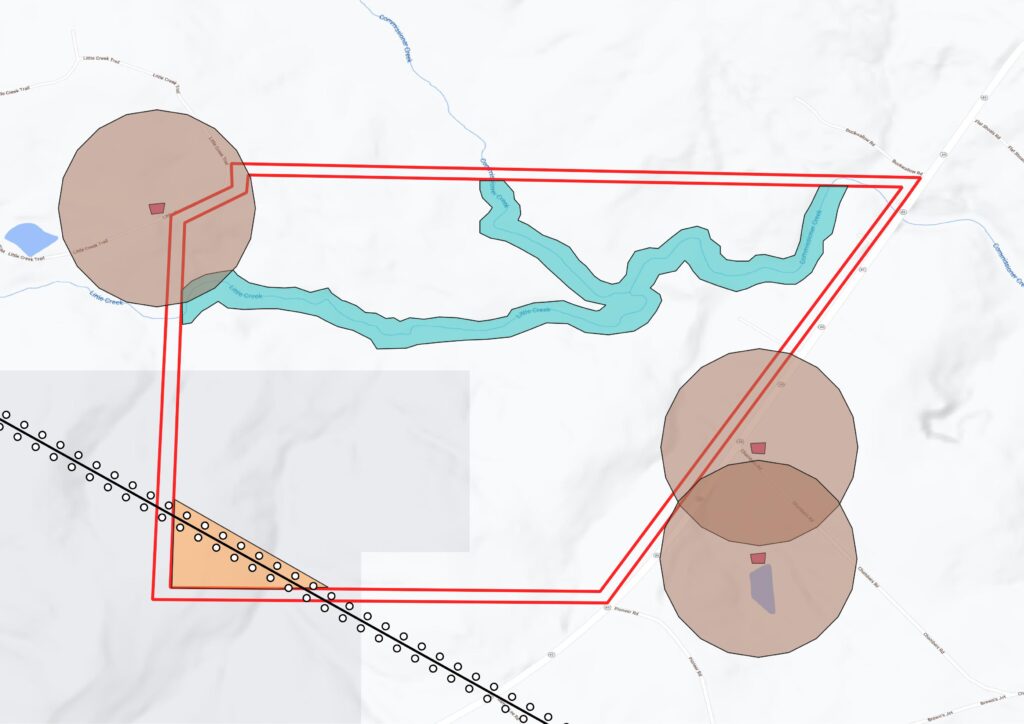

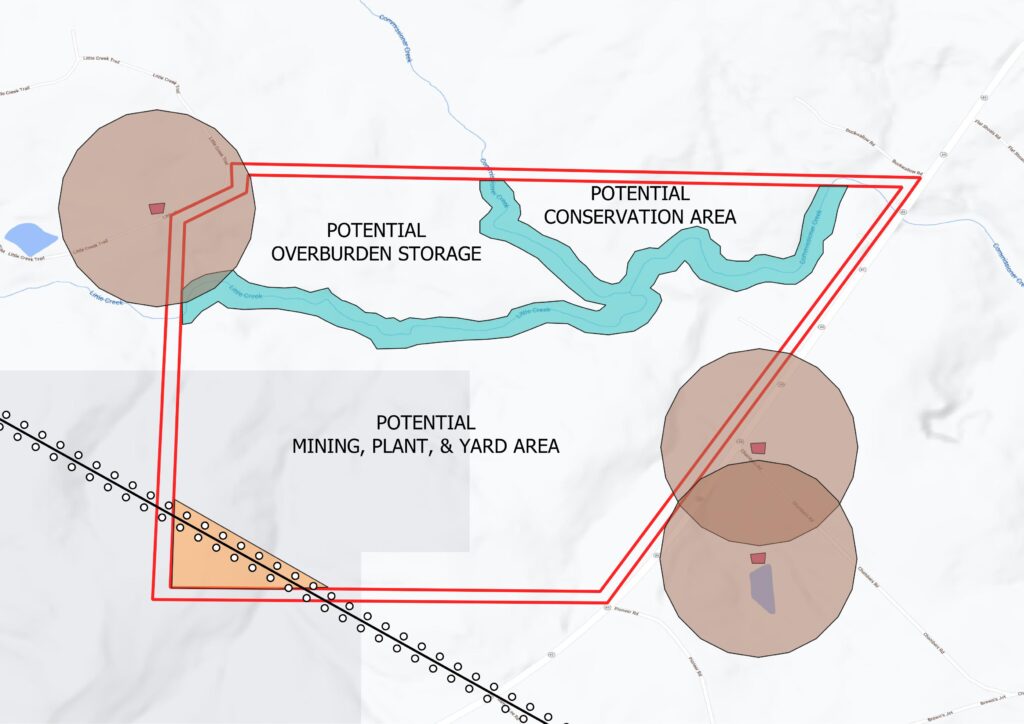

Intensive planning before breaking ground can have a profound impact on the sustainability of a quarry. Leveraging the expertise of seasoned professionals, such as those from Burgex Mining Consultants, can greatly optimize this process.

Efficient Pit Designs: By modeling the deposit and understanding the geological contours, quarries can design pits that follow the natural layers of aggregates. This allows for a more streamlined extraction process, minimizing waste and energy consumption. Burgex’s team, with their extensive experience, can provide invaluable insights into maximizing the efficiency of pit designs.

Optimal Routing: Within the quarry, the routing of machinery and transport vehicles plays a crucial role in efficiency. Shorter routes and fewer idle times for machinery, achieved through intelligent routing based on real-time conditions, can lead to substantial fuel savings. Collaborating with experts like those at Burgex can help operations fine-tune their internal routing for maximum efficiency.

Methodical Extraction Sequences: By planning the sequence of extraction, quarries can ensure that they’re always working on the most accessible and easiest-to-extract areas. This reduces the time machinery spends breaking and moving material, decreasing fuel consumption and machinery wear. Again, tapping into the knowledge base of mining consultants can refine this sequencing.

Future-proofing with Scalability: Good planning also involves considering future expansions and deeper excavations. By keeping future scalability in mind, operations can ensure that their initial designs don’t lead to inefficiencies or extensive modifications later on. A partnership with Burgex can be instrumental in providing a long-term vision, ensuring that the site remains both productive and eco-friendly in the years to come.

3. Integrate Aggregate Recycling Facilities On-Site

Incorporating recycling practices into your operations not only reuses materials but also reduces the need for virgin extraction, saving energy and reducing environmental impacts.

On-site Processing: Having a dedicated area for the recycling and processing of old aggregates means that materials can be reclaimed and repurposed directly on-site. This eliminates the need for transport to external recycling facilities and reduces the demand for virgin materials.

Source External Waste: Encourage local construction projects to send their waste concrete and asphalt to your facility. By recycling this material into new aggregate products, you’re diverting waste from landfills and reducing the energy and resources required to produce new aggregate from scratch.

Diverse Product Offering: Aggregate recycling can produce a variety of products, from base materials for roads to high-quality aggregates for new concrete. Offering a diverse range of recycled products can help cater to different market needs, potentially opening new revenue streams.

Promote the Green Initiative: Beyond the environmental benefits, promoting the fact that your operation recycles can be a unique selling proposition. It can appeal to eco-conscious customers and businesses looking to boost their own sustainability credentials by sourcing recycled materials.

4. Utilizing Energy-Efficient Machinery

Incorporating energy-efficient machinery into the mining and processing operations can drastically reduce the carbon footprint and operational costs of a quarry.

Modern Equipment: Newer machinery models are typically designed with fuel efficiency and reduced emissions in mind. Investing in modern excavators, loaders, crushers, and haul trucks can mean burning less fuel for the same amount of work. It’s not just about engine efficiency—advanced hydraulic systems, better aerodynamics, and smarter computer controls all contribute to improved energy usage.

Hybrid and Electric Machinery: As the construction and mining industries evolve, there are more options available for hybrid and electric machinery. These machines offer the potential for zero on-site emissions and can be powered by renewable energy sources. They also tend to have fewer moving parts, which can reduce maintenance needs and downtime.

Automated Systems: Automation in machinery can lead to more consistent operation, minimizing wasteful practices. For instance, automated load and haul systems can optimize routes in real-time, ensuring trucks take the most efficient path and are loaded to their optimal capacity.

Regular Maintenance: Keeping machinery well-maintained ensures that it operates at peak efficiency. This includes regular oil changes, filter replacements, and engine tune-ups. Dirty or poorly maintained equipment can consume more fuel and produce more emissions.

Operational Training: Ensuring that operators are well-trained can have a significant impact on fuel consumption. Operators who understand the most efficient ways to use their machinery can reduce unnecessary idling, optimize loading techniques, and generally ensure that the equipment is used in the most energy-efficient manner possible.

Monitoring and Reporting: Using technology to monitor the fuel consumption and efficiency of machinery can be invaluable. Real-time monitoring systems can provide instant feedback, allowing for adjustments in operations. Regular reporting can identify trends, leading to better long-term decision-making about equipment and practices.

By emphasizing energy efficiency in equipment selection and operation, quarry owners can realize both environmental and economic benefits. Reduced fuel consumption translates to lower operating costs, while reduced emissions and a smaller carbon footprint can enhance the operation’s sustainability profile.

5. Implementing Natural Habitat Restoration

The environmental impact of quarrying extends beyond just the extraction phase. When planning a greenfield site, considering the end-use and eventual restoration of the mined area can make a significant difference in terms of ecological benefit and public perception.

Phased Restoration: Instead of waiting until the end of the quarry’s life, consider restoring areas in phases as they become exhausted. This approach can quickly return portions of the land to a more natural state, allowing ecosystems to begin their recovery process sooner.

Native Plant Reintroduction: Use native plants in the restoration process to ensure the returned land is suitable for local wildlife. Native plants help prevent soil erosion, maintain local water quality, and provide habitat and food sources for native species.

Water Management: Many quarries end up with significant water features post-mining. Properly managing these can create valuable wetland habitats. This might include measures to ensure clean water, managing water levels for wetland birds, or introducing native fish species.

Collaboration with Ecologists: Partner with local ecologists and conservationists to determine the best restoration strategies. They can provide insight into what species may be most beneficial to reintroduce and how best to structure the landscape for biodiversity.

Community Engagement: Involve the local community in the restoration process. This could be through educational programs, community planting days, or simply keeping them informed about the restoration progress. A community that feels involved and informed is more likely to support the restoration efforts.

Post-Restoration Monitoring: Even after restoration, it’s essential to monitor the land to ensure the intended ecosystems establish and thrive. This might involve tracking plant growth, surveying for wildlife, or ongoing water quality tests.

A well-implemented restoration plan not only mitigates the environmental impacts of quarrying but can also transform exhausted quarries into valuable community and ecological assets. Whether they become local parks, wildlife habitats, or community water features, restored quarries can play a vital role in local ecosystems.

6. Water Conservation Strategies

In many regions, water is a precious resource, and its conservation within the aggregate industry isn’t just good for the environment; it’s often an economic necessity. Here are strategies that emphasize sustainable water use:

Closed-Loop Water Systems: Use a closed-loop system that recycles and reuses water in the quarrying process. Such systems substantially reduce the demand for fresh water by continually treating and reusing the same water in operations.

Rainwater Harvesting: Implement rainwater harvesting systems to capture and store rainwater. This harvested water can then be used for various site operations, including dust control, washing, and even in restorative processes.

Drought-Resistant Landscaping: For any landscaping or restoration activities, choose native or drought-resistant plants that require minimal irrigation.

Evaporation Prevention: Large water bodies, often a byproduct of quarrying, can lose significant amounts of water through evaporation. Implementing floating covers or shade balls can reduce evaporation rates.

Advanced Filtration Systems: Utilize modern filtration systems that can treat and purify water more efficiently, ensuring that a greater volume is available for reuse.

Regular Monitoring: Regularly monitor water usage and identify any leaks or inefficiencies. Small, unnoticed leaks over time can result in significant water loss.

Educate Employees: Ensure that all staff are educated about the importance of water conservation and are trained in best practices to minimize waste.

Engage with Local Water Authorities: Collaborate with local water boards or authorities to understand regional water concerns and get guidance on best conservation practices tailored to the area.

Water conservation isn’t just an environmental concern; it’s also an operational one. By reducing the demand for fresh water and maximizing the reuse of existing supplies, aggregate producers can ensure more sustainable, long-term operations while also lowering operational costs.

7. Noise and Dust Reduction

The environmental footprint of an aggregate operation isn’t just about land and water; it extends to the air and sound environment as well. Reducing noise and dust not only benefits the environment but also the surrounding communities and the overall public perception of the operation. Here’s how quarrying operations can tackle these two pervasive challenges:

Advanced Machinery: Utilize machinery that is designed to produce less noise. Modern equipment often comes with improved sound dampening and controls that minimize their acoustic footprint.

Strategic Planting: Planting trees and shrubs around the site’s perimeter can act as a natural barrier to both noise and dust, aiding in their absorption.

Dust Suppression Systems: Invest in state-of-the-art dust control systems, which can range from misting cannons to foam suppression technology, to keep dust levels down.

Proper Maintenance: Regularly service machinery to ensure they operate efficiently and quietly. A machine in good repair is typically quieter than one that’s worn out.

Operational Timing: Limit the loudest operations to the middle of the day when background noise is generally higher, and fewer people are likely to be disturbed.

Haul Road Maintenance: Regularly maintaining and dampening haul roads within the site can reduce the amount of dust kicked up by transport vehicles.

Noise Barriers: In areas particularly sensitive to noise, consider erecting temporary or permanent noise barriers. These can be in the form of earthen berms, acoustic fences, or specialized panels.

Regular Monitoring: Utilize noise and air quality monitors to continually check the levels of noise and particulates emanating from the site. Monitoring helps ensure compliance with regulations and can highlight areas that need attention.

Community Engagement: Engage with the local community to understand their concerns about noise and dust. An open dialogue can lead to tailored solutions and foster goodwill.

Being proactive in reducing noise and dust can drastically improve community relations and make the permitting process smoother in expansions or new ventures. It’s a tangible way of showing commitment to sustainability and corporate responsibility.

Conclusion

In today’s world, it’s not enough to just mine aggregates; it’s essential to do so responsibly, considering the environment, communities, and the future. As we’ve explored, the strategies for eco-friendly quarrying are multifaceted, ranging from optimizing transportation to pioneering noise and dust reduction techniques. Every step in the right direction, whether it’s investing in energy-efficient machinery or implementing water conservation strategies, counts towards a larger goal of sustainable aggregate production.

Moreover, embracing these practices isn’t just about responsibility—it’s also about forward-thinking business. As communities become more environmentally conscious, adopting green practices will not only foster positive community relations but also potentially pave the way for smoother permit approvals and renewed licenses in the future.

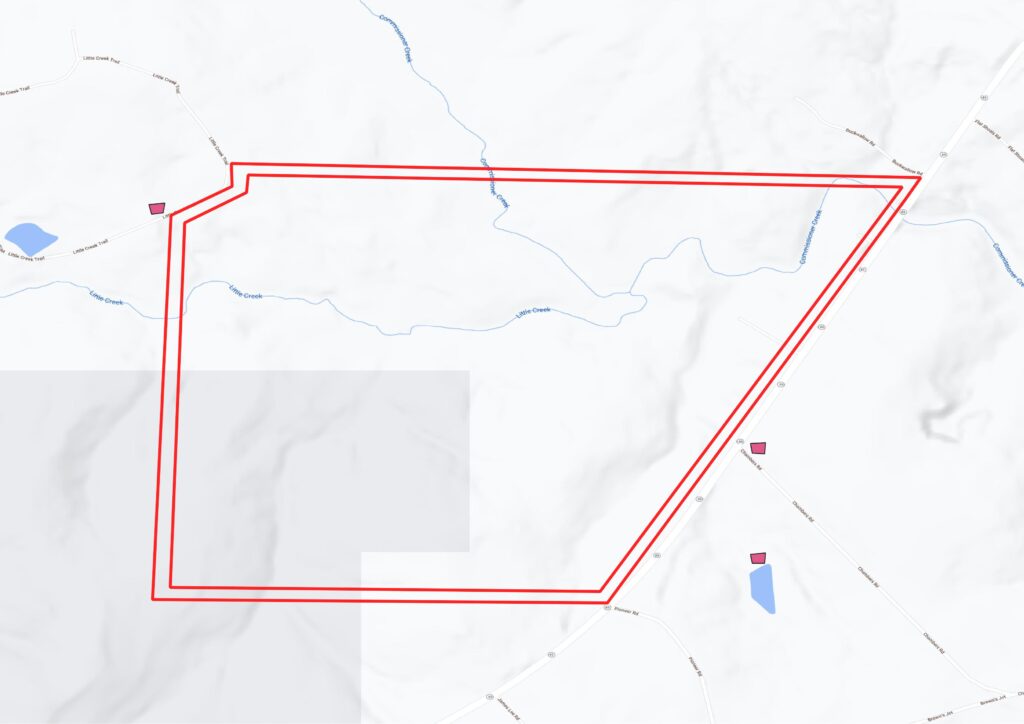

With the right partners, like Burgex Mining Consultants, and resources like Mineralocity Aggregates that provide invaluable insights for greenfield site selection, aggregate producers can be well-equipped to navigate the intricacies of sustainable operations. As we look ahead, the merging of industry and eco-conscious practices will undeniably be the hallmark of leading aggregate producers worldwide.

Ready to Unlock the Secrets of Successful Greenfield Site Evaluation?

Dive deeper into the world of construction aggregate production with our exclusive Greenfield Guide. Whether you’re a seasoned expert or just embarking on your aggregate adventure, this guide is your roadmap to identifying prime locations, assessing supply potential, and capturing significant market shares. Arm yourself with proven strategies, actionable insights, and essential formulas designed to propel your projects to unparalleled success. Don’t miss this chance to elevate your greenfield endeavors – grab your free copy of the Greenfield Guide now!